The oil and gas industries need very accurate measurements in order to perform the operations efficiently. To achieve the desired results, a proportional pinch valve is a device that can help these industries. This valve lets them adjust the flow of gas or oil as per their needs.

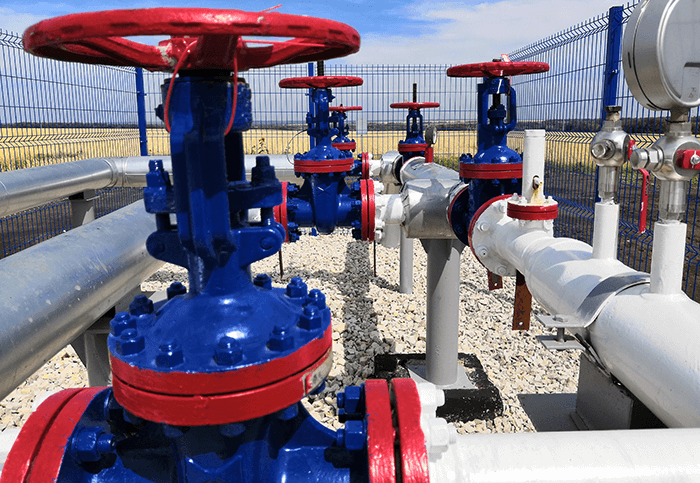

1. Flow Control in Pipelines

Pipes are usually used to move oil, gas, and slurries (a mix of liquids and solids). In these pipelines, it’s very important to control how slow or fast the fluids move. So, a proportional pinch valve is used on these pipelines to adjust the flow very smoothly. This control is really helpful, especially when you need to mix the right proportion of chemicals or when you need to move crude oil to the exact tanks.

2. Maintaining Accurate Meter Readings

Meters tell operators how much fluid moves. When the flow swings, the meters give wrong numbers. So, a pinch valve fixes this problem by keeping the flow smoother and consistent. This way, the meter gives the correct reading every time, which helps in better decision-making.

3. Protecting Equipment from Abrasive Materials

Some fluids carry rocks or sand, and they can scratch metal. A pinch valve squeezes a soft sleeve so only that sleeve wears. Workers replace the sleeve faster and cheaper than a full metal part.

4. Safety Features in Pressure Control

If pressure jumps, the device reduces flow fast but calmly. Operators set simple guidelines, and the valve automatically adjusts the flow to stay within those limits. By managing pressure carefully, the pinch valve helps lower the risk of accidents and keeps everything running safely.

5. Precise Control for Testing and Research

The test setups and small rigs need a lot of accuracy in fluid control. Engineers use a proportional pinch valve to adjust the flow exactly as needed for experiments and research. The device gives repeatable results, so tests match each other.

6. Reducing Spare Part Costs

Pinch valves have a replaceable sleeve that can wear out over time. When this happens, instead of replacing expensive metal parts, teams simply swap out the sleeve. This is much cheaper and quicker. Plants keep a few sleeves and fix things quickly.

Why teams pick this valve

- It controls flow smoothly.

- It protects parts from abrasive fluids.

- It works well with soft or sticky substances.

- It can act fast in safety moments.

These simple reasons make it common across a plant.

Quick checks for using one

- Fluid has solids or stickiness.

- The team needs smooth control.

- The meter needs a steady flow.

- Spare budgets favor sleeves over full parts.

Simple tips for care

- Check the sleeve regularly.

- Clean around the valve so that debris does not gather.

- Keep a spare sleeve on hand.

- Train staff to spot sleeve wear early.

A short story to remember it

Think of a soft rubber straw in a toy pump. Squeeze the straw gently, and the water slows. Squeeze harder, and more water comes out. That is how the valve works in a big plant.

Wrap up

The proportional pinch valve helps plants control flow, protect parts, keep meters honest, act in safety moments, and save money on parts. It fits the places where fluids are rough or tricky. When operators need smooth, simple control, they choose this device.

Real-world example

On a small platform, teams move produced water and mud through short pipelines. They install a pinch valve on the line that carries a sand and oil mix. Operators set the control to change the flow slowly during start-up and stop. This prevents sudden pushes on meters and pumps. The maintenance team checks the sleeve each week, cleans soft parts, and logs hours of use. When the sleeve wears, they swap it during a short stop. This routine keeps the line running and saves money.

Final note

Teams should test the control settings before full use. A short trial run catches issues. Keep a log of sleeve hours and service dates so small fixes do not grow into big problems.