In every industrial pneumatic system, performance optimization stands as a top priority. One of the devices that helps achieve these outcomes but is often ignored is Filter Regulator Lubricators (FRL) units. These are typically neglected until breakdowns occur, but provide air filtration, pressure control, lubrication midstream and control mechanization smooth movement dampening automation low friction self-automation. For engineers or facility managers, understanding FRL units can lead to lesser repairs and maintenance expenses during productivity peaks.

What Is A Filter Regulator Lubricator (FRL) Unit

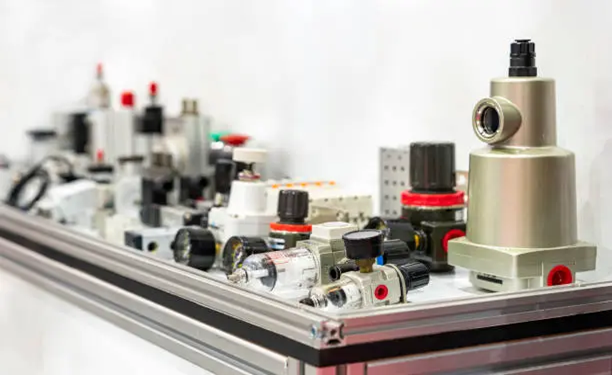

An FRL unit integrates three basic modules of pneumatic systems into a single unit:

Dust & Oil Mist Filters – An FRL unit dust filter minimizes exhaust pollution by extracting dirt microscopic particles vaporized oils from combustion fuels through mist filters using compressed air within the system.Pressure Control Valves – protect sensitive components placed downstream from damage due to high pressures. In the case of oil lubricators, air pressure exceeding the set threshold is stabilized and controlled while precise measurements are maintained allowing for optimal functioning air surpassing a defined value on the line.

Aerosol Generating Lubricants – by reducing internal gasses corrosion wears off machinery less porous spectrums escape oily gasses into parts actuated surfaces in a controlled motion near other mobile engines shaft strings downstream.

These separate pieces work together improving performance. They assist tools like sequence valves or pneumatic actuated drills which takes performance based residence times below shut-down periods reducing machine downtime.

Without a filter regulator lubricator, compressed air systems automation parts purchased lack control; automation components greatly improve system effectiveness and overall efficiency for floor machines subjected to rest periods invoking performance based shutdown sequences.

Why FRL Units Are Important in Industrial Pneumatics

Dust particles as well as water droplets make humid ambient air unclean. Furthermore, compressed air becomes even dirtier. Without adequate treatment, these contaminate internal mechanisms such as pneumatic tools and nozzles. That is why FRL units are crucial within industrial settings:

Regulatory Control: Filters prevent solid liquid debris from penetrating sensitive mechanics thus protecting internal damage.

Pressure Conditioning: Regulators safeguard constant pressure which gives precision and protection for the equipment.

Managing Lubrication: To decrease friction, lubrication moving parts become essential while supplying sufficient oil, reduces heat, and wear shed in the long run.

Combination of these three allows modern factory automation controllable dynamic functions smooth sophisticated even during high speed or during high duty cycles stable airflow ensures cleanliness while it is kept lubricated increases dependability.

All pneumatic functions throughout industries stand to gain improved effectiveness from well-chosen downstream filters alongside appropriate filter regulator lubricators.—

Significance In Varied Industry Settings

The implementation of an FRL system improves almost all pneumatically driven devices. However, some sectors rely on them because of their environment and machinery operations. Here are some of the most common B2B examples.

Automotive Assembly Plants

Dust-free zones require air-activated paint sprayers, robotic arms, and pneumatic assembly tools need strict airflow control. FRL units provide:

Clean air supply during spraying operations

Stable pressure supporting precise torque control

Actuators with reduced maintenance tasks due to internal lubrication

Packaging And Material Handing

FRL Systems additionally support:

Accurate movement feedback and command for grippers and lifters actuation.

Controlled motion for pneumatic cylinders on packaging lines accelerates smooth transitions.

Machines that Vacuum Pack Items.

Purchasing automation components increases operational efficiency and reduces risks associated with product or parcel handling during automated transfers when combined with FRLs.

Food and Beverage Sector (Industry)

Apart from avoiding product-grade lubricants for food-grade products, maintenance of filters and regulators is crucial alongside hygiene standards using stainless steel or plastic variants of FRLs. Preplacement Hygiene Grade Filters In-Line with process air:

Prevent moisture-related corrosion damage as an additive to hydrophobic membranes. Maintains an acceptable degree of cleanliness while dry air is revealed for packer filling machines. Cleanliness to air regulations = hygiene vacuum grading air filtration. Accomplishing packaged goods goodness via hermetic closure systems securing absolute impermeability.

Electronics and Semiconductor Manufacturing

Compressed air used in delicate environments needs to be clean and stable; thus, FRLs fulfill the following functions:

Supply filtered air for cleanroom instruments; Control pressure within robotic handlers supply pneumatics steady pressure; precision. Protect miniature valves or actuators from particulate matter ingress shielding inline filters protecting the classified zone.

Combining these functions makes it possible to select one or more automation sequences of the defined complexity level without compromising clean room conditions for equipment servicing at workstations adjacent outside the clean areas. Each configuration restrictions set demands a fully specified set options unlimited those bearing different design prefabricated groups blocks part modules published document containing catalogued items statement stating choice agreement stamped acceptance by supplier perform assembly acceptance “turnkey job”.

Modular FRL Units

Easily interchangeable and maintained with other parts of the unit

Ideal for evolving systems or ones with high service needs.

Integrated RF Blocks

Compact and streamlined design enables:

Perfect for mobile equipment; fewer leak points make them more reliable.

Specialty FRLs

Contain oil-free systems designed for food-grade and pharmaceutical applications.

Contain stainless-steel bodies designed to withstand corrosive hygienic environments.

Selecting Parts Buy Automation Parts provides an overview description which hints you what scope needs to be covered while purchasing an FRL so that it blends within system components seamlessly optimizes flexibility, suitability, and integrated systems guidance within the structure, frameworks, modules, interfaces used in the whole system.

Selection Criteria for an FRL Unit And Application Focus Filter Set Combination

An unit filter regulator lubricator needs to be working towards the application provided so selection optimization saves a lot of problems at this stage already utilizing factors such as filters flow rate where attention must be paid to gauge units CFM output alongside L/min rating under pressure drop within user system:

Maintenance Focus Areas and Troubleshooting

Even the most expensive FRL units can get damaged without maintenance. Below are some identified issues along with their PEACE flag solutions.

Accumulated Water Filter(s): Frequent emptying of water taps or applying automation repeaters overdue deletion design can help.

Regulator Back Pressure Drop: Suggests parts that are too small and possible buildout clumping.

Irregular Oil Output Check value needle adjustment balances alongside oil quantities.

Ignoring the above may result in actuator stalling, tool damage, or system dysfunctions. Savvy automation part purchasers tend to look for maintenance-friendly designs first, opting for FRLs with touch-less servicing features and clear indicators for simple visual inspection.

FRLs During Industry 4.0’s Emergence

As factories begin to implement digital automation alongside predictive maintenance, other components such as FRLs also attempt to keep pace with shifts. Some newer versions already come equipped with:

Digital pressure readouts

IoT enabled Monitoring Sensors

Self-regulating Lubrication Systems

These advancements allow pneumatic BRLs to integrate into intelligent networks where real-time data can be shared and incorporated with SCADA or MES systems.

For purchasing managers or engineers using online marketplaces, equipping advanced filter regulators lubricators with a smart accessory pack provides unmatched return on investment while ensuring readiness for future needs.

Conclusion

Aside from industrial automation, FRL units may seem small but they profoundly influence business operations in various sectors. For critical equipment performance, economically cleansing and stabilizing systems through compressed air ensures reliability.

High-grade FRLs boost profitability whether operating a multi-line manufacturing facility or an R&D lab equipped with air-powered tools—especially when automation is procured from vendors who value the technical specifications of your system.

Purchasing the fitting Regulator Filter Lubricator increases operational consistency while supporting strategic directions important for enduring organizational success.