Introduction

In today’s fast-paced world of e-commerce, logistics, and global trade, foam inserts for boxes have become one of the most reliable solutions for protecting products during transport. Whether you are shipping delicate electronics, luxury jewellery, or heavy industrial parts, the need for secure and efficient protective packaging has never been greater. Traditional methods such as bubble wrap or loose-fill packaging may offer some cushioning, but they often fail to deliver the precision and reliability required for fragile or high-value items.

This is where engineered foam packaging solutions, including polyethylene packaging and polyurethane inserts, play a vital role. By combining science, design, and customisation, foam packaging ensures that products reach their destination safely while also supporting sustainability and efficiency in supply chains.

Why Foam Inserts for Boxes are Essential

A product’s journey from warehouse to customer is often unpredictable. It may face vibrations during transit, sudden impacts, exposure to moisture, or stacking pressures in warehouses. Foam packaging is specifically designed to counter these risks:

- Shock absorption: Foam absorbs impact forces, reducing the risk of cracks, dents, or breakage.

- Precision fit: Custom foam inserts cradle products securely, preventing movement inside the box.

- Versatility: From small electronics to oversized equipment, foam packaging can be tailored to fit any shape or size.

- Presentation: Beyond protection, foam adds a professional appearance, improving the unboxing experience for customers.

For businesses in industries like healthcare, aerospace, automotive, and electronics, these qualities are not optional—they are essential.

Types of Foam Packaging and Their Applications

1. Polyurethane Packaging

Polyurethane is widely recognised for its role in bedding and furniture, but its packaging benefits are equally impressive. Lightweight, flexible, and resilient, it is particularly suited for fragile and delicate items such as ceramics, medical devices, or jewellery.

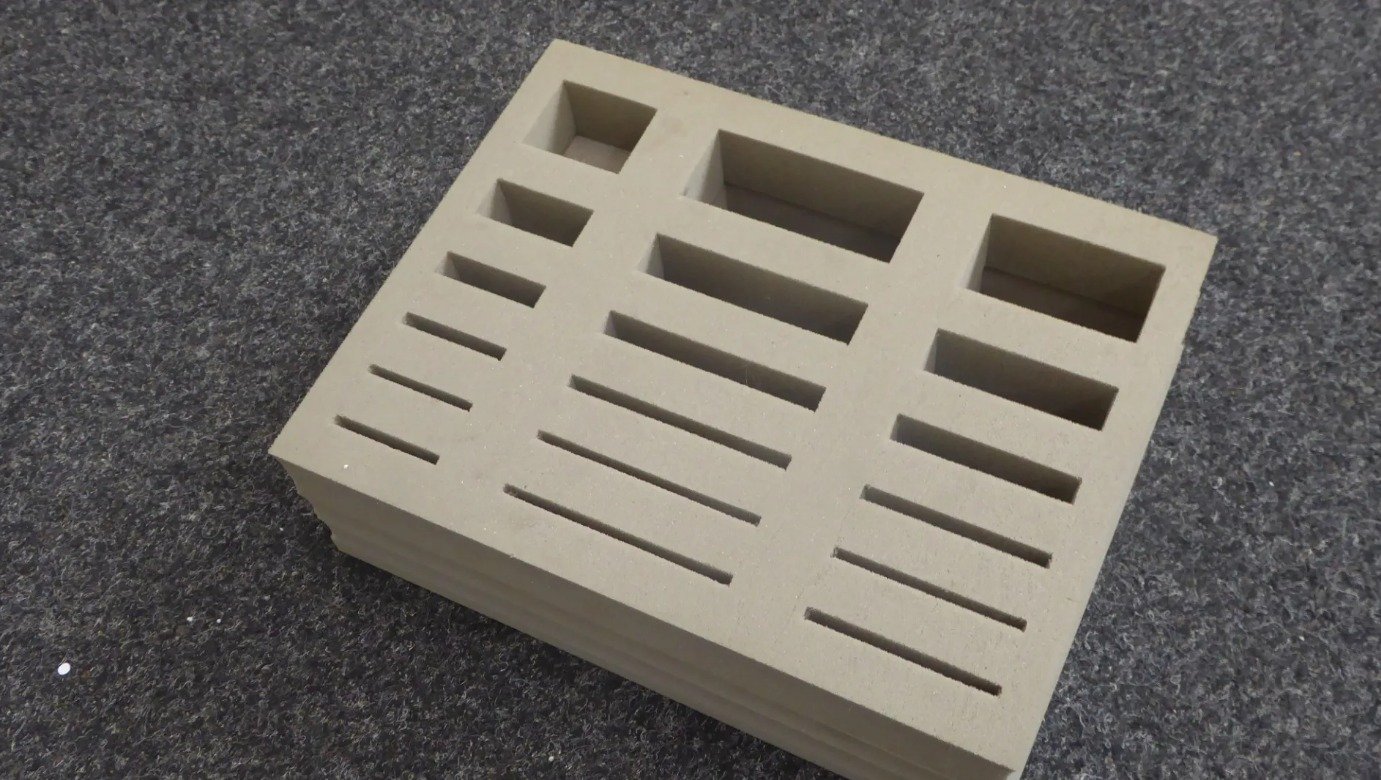

- Can be cut, pressed, or shaped into “egg box” foam with peaks and troughs that hold different items securely.

- Dust-free, making it ideal for clean industries like healthcare and electronics.

- Available in multiple colours and densities, allowing companies to choose a finish that matches their branding or functional needs.

2. Polyethylene Packaging

Polyethylene packaging is one of the most popular options for businesses that need a tough, moisture-resistant solution. Unlike polyurethane, polyethylene foam is closed-cell, giving it greater rigidity and water resistance.

- Ideal for automotive components, metal parts, and heavy-duty goods.

- Recyclable and available in multiple densities.

- Performs well in high-volume shipping operations due to its durability and cost-effectiveness.

This material has become a preferred choice for companies looking to balance performance, sustainability, and affordability.

3. Polystyrene Packaging

Rigid yet lightweight, polystyrene foam offers strong thermal insulation and impact resistance. It is often used for electronics, appliances, and goods that require an extra layer of protection during long-haul shipping.

4. Nomafoam

With its vibration- and abrasion-resistant qualities, Nomafoam is commonly used for sensitive instruments and high-end goods. Its clean finish makes it particularly suitable for luxury products that require both protection and aesthetics.

The Science Behind Protective Packaging

Protective packaging is not just about cushioning; it’s about engineering safety. Companies like Advanced Protective Packaging apply real-world testing to ensure materials meet industry standards. Testing methods include:

- Drop tests to measure impact resistance.

- Vibration simulations to replicate long-distance transportation.

- Climate control simulations to test packaging in different temperature and humidity conditions.

This scientific approach helps minimise damage, reduce returns, and build trust between businesses and customers.

Benefits of Foam Inserts for Boxes

1. Maximum Product Safety

The primary purpose of foam packaging is protection. Foam inserts are designed to keep products immobile inside the box, reducing the risk of internal collisions or external impacts.

2. Cost Efficiency

By reducing damages and returns, companies save money in the long run. Polyurethane and polyethylene packaging also offer excellent durability, meaning they can be reused multiple times.

3. Professional Presentation

Foam inserts enhance the presentation of products. For businesses shipping luxury goods, the packaging itself becomes part of the customer experience. A neatly fitted foam insert demonstrates attention to detail and care.

4. Sustainability

With increasing awareness of environmental impact, recyclable packaging materials such as polyethylene and corrugated cardboard are more in demand than ever. Foam inserts can be designed to reduce material waste while maintaining strength.

5. Convenience and Efficiency

Buying foam inserts and boxes from a single supplier ensures compatibility, simplifies paperwork, and avoids stock imbalances. Businesses can also order complementary products such as tape and pallet wrap, creating a one-stop packaging solution.

Industries That Rely on Foam Inserts

- Electronics – Protecting delicate circuit boards, sensors, and devices.

- Medical – Ensuring surgical tools, implants, and devices arrive sterile and undamaged.

- Aerospace – Safeguarding precision components that must remain intact under strict tolerances.

- Jewellery & Luxury Goods – Combining protection with elegant presentation.

- Automotive & Industrial – Using polyethylene packaging to transport metal parts and heavy machinery.

Customisation: Tailored Protection for Every Product

One-size-fits-all packaging rarely works. Modern packaging specialists use advanced CAD software to design foam inserts that fit products like a glove. The process often includes:

- Consultation to understand the product’s unique needs.

- Material selection based on fragility, weight, and environment.

- CAD prototyping and 3D modelling.

- Real-world testing to verify durability.

- Full-scale production for consistent supply.

This approach not only enhances safety but also improves brand identity by offering customised colours, finishes, and even logo embossing on foam inserts.

Additional Tools that Complete the Package

Foam inserts are often paired with other packaging tools to provide full protection:

- Packaging tapes – Essential for sealing, branding, and theft prevention.

- Stretch and pallet wraps – Stabilise bulk shipments and guard against dust and moisture.

- Corrugated boxes – Provide outer structural strength while foam inserts protect the inside.

Together, these elements create a complete protective system.

Conclusion

In the modern supply chain, foam inserts for boxes are more than just fillers—they are precision-engineered tools designed to protect, present, and enhance products. Whether you choose polyurethane for its flexibility or polyethylene packaging for its toughness and recyclability, foam solutions ensure goods arrive in perfect condition.